The ideal solution for complex industrial components

29 January, 2026In the context of modern industrial metal fabrication, tube laser cutting is a strategic tool for improving production efficiency, assembly quality, and the reliability of the final component.

For companies that design and manufacture industrial machinery, refrigeration units, automated systems, or light metal structures, tube laser cutting provides a concrete answer to increasingly complex design requirements.

When tube laser cutting really makes the difference

Tube laser cutting is particularly suitable when the component is not a simple structural element, but an integral part of a mechanical system or a complex assembly.

It is the ideal choice in the presence of:

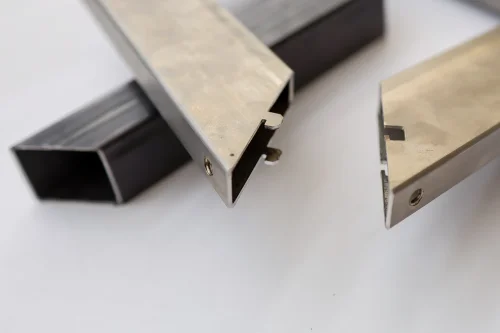

- tubular structures with multiple holes, slots, and shaped features

- components intended for precise and repeatable welding

- the need for perfect fits between tubes and plates

- components that must minimize tolerances during assembly

In these cases, traditional machining would require multiple steps and reworking, increasing lead times and indirect costs.

Reduction of processing steps and assembly time

One of the main reasons companies choose tube laser cutting is the streamlining of the production process.

Tubes leave the process already drilled, shaped, and ready for welding or assembly, eliminating subsequent manual operations, reducing positioning errors, and speeding up assembly lines.

This advantage is particularly significant for medium-to-large series production, where process repeatability is essential.

Perfect integration with welding and surface treatments

Tube laser cutting is even more effective when integrated into a complete production flow.

F.X.T. S.p.A. supports customers not only during the cutting phase but also in subsequent operations, delivering finished, ready-to-use components.

The precision of laser cutting enables:

- cleaner and faster welding

- more stable mechanical joints

- better results in surface treatments

Industrial applications of tube laser cutting

Tube laser cutting is used across a wide range of industrial sectors, including:

- machinery for the food industry

- refrigeration units and HVAC systems

- structures for automated machinery

- lightweight metal frames and supports

In all these fields, the combination of precision, reliability, and production continuity is a decisive competitive factor.

Certified materials and quality control

F.X.T. S.p.A. uses guaranteed and certified materials, selected to meet the technical and regulatory requirements of the most demanding industrial sectors.

Attention to raw material quality and material traceability represents added value for structured companies that require reliable suppliers compliant with industry standards.

Thanks to consolidated experience in medium-light metal fabrication and technologically advanced systems, F.X.T. is the ideal partner for projects requiring expertise, precision, and long-term reliability.

Contact us to evaluate together the most suitable solution for your project.

Do you want to know more?

Contact us without obligation